High-Rise Firefighting / Standpipe Operations

Engine Company Standpipe Hosepack

The “Denver Hosepack”

Welcome back, and thanks for staying engaged. In a previous post, I addressed the concept of proper weapon selection, and the critical need to choose and utilize 2 ½-inch hose for most high-rise / standpipe operations. Far too many well intentioned fire officers, choose their high-rise / standpipe attack weapon based on a one-dimensional size-up. That is, they choose the weapon based on fire conditions alone. The fire conditions showing upon arrival may in fact be fire conditions that can be quickly and safely controlled by a properly supplied 1 ¾-inch attack line. However, and more specifically, that would be a 1 ¾-inch attack line, supplied by our pumper and pump operator (engineer), and within immediate reach of the fire area. Our most frequent fire, in a single-family dwelling, first floor, easily accessible by a 200-foot pre-connected attack line is a prime example.

However, we must be multi-dimensional thinkers as we size-up a fire problem, and make a conscious decision regarding weapon selection, especially at high-rise fires and standpipe operations. The critical factors to make a multi-dimensional decision are:

- Standpipe System Pressure, which has a high probability of being Low Pressure.

- Modern fuel loads, with their rapid heat release rate.

- Reflex time, which will likely be significant at high-rise building fires, and any fire that requires the use of a standpipe system.

Put these critical factors together, and the synergistic effect will guide us toward accurate fireground decision-making. The logical weapon selection choice being our high volume, low-pressure weapon, the 2 ½-inch attack line for most high-rise / standpipe operations.

So, as you look up from the street and see fire showing from a 25th floor apartment window, remember, you must be realistic, especially regarding your reflex time. What you see showing from the street upon arrival, might just be the “tip of the iceberg”. Because of significant reflex time at a high-rise fire, conditions on the fire floor could be much more significant by the time you get up there.

Given ample oxygen and fuel, the fire is going to grow exponentially, likely doubling in size every half minute. On your best day (or night), your reflex time to get to the 25th floor, properly stretch a line, get water, and initiate attack, could be twenty or more minutes. Remember that single-family dwelling fire we talked about previously? What if, at our next single family dwelling fire, we arrive on scene, the engineer (driver) sets the air brake, but instead of immediately going to work, we stay inside the pumper for 20-minutes. Ridiculous? Yes, I know. But the point is, what’s that dwelling fire going look like with no fire department intervention for 20-minutes? Now put it back up on the 25th floor. Not so ridiculous, is it? Don’t forget, your 25th floor fire problem is obviously going to require a standpipe system, and low system pressure is highly probable. There you have it, the multi-dimensional approach necessary for proper weapon selection at fires in high-rise and standpipe equipped buildings.

Keep in mind, much of our time and work associated with training on 2 ½-inch hose, is spent trying to convince the masses that 1) we need to use it, and 2) we can move it. So, with that said, if you believe it’s a necessary weapon, we must take the steps to make it doable.

In my textbook, I address several keys to success when using 2 ½-inch attack line. One of those critically important items is:

- User-friendly high-rise / standpipe hosepacks.

Specifically, a high-rise / standpipe hosepack should be:

- Light weight

- Tight and compact

- Easy and comfortable to carry

- Easy and quick to deploy

The high-rise / standpipe hosepack used by the Denver Fire Department (DFD), the “Denver Hosepack” meets all of those criteria. The development of this hosepack started over twenty years ago in 1992. Since that time, the “Denver Hosepack” has undergone numerous revisions and minor alterations to enhance and improve its efficiency and effectiveness.

Let’s start with weight. The weight of a hosepack is one of its most important characteristics. Historically, many fire departments across the fire service have employed a one size fits all hosepack. In other words, there is often a very large, bulky, heavy hosepack, usually consisting of several sections of hose, and all of the other tools and appliances necessary to mount a fire attack using a standpipe system. There are countless gimmicks and methods on the “Web” suggesting how to carry and deploy a standpipe hosepack. In some cases suggesting that we cram everything, including the kitchen sink, into a large, body bag like container, and call it a hosepack. Have you ever weighed any of these ridiculous hosepacks on a scale? I certainly have. And in my research, I have found some of these hosepacks to weigh in excess of 100-pounds. Who’s carrying these gigantic packs up to the 25th floor? Yes, I know, the junior guy. Or we have a dolly for the hosepack. What happens when the elevators are out of service? Crazy!

One of my recommendations regarding high-rise / standpipe hosepacks, is rather than having a so-called “one size fits all” hosepack design (and one size does not fit all), I recommend that you assemble, and utilize a modular equipment package. Specifically, the hosepack is not a single hosepack, but rather several hosepacks, and an associated standpipe equipment kit (tool bag) of which, a fire attack group, or team of firefighters, using teamwork, carries all of the equipment up to the point of operation, in small, manageable, and lightweight pieces. By doing so, we can take all of the necessary and appropriate equipment, but we are dividing the labor of carrying it up to the 25th floor.

Specifically, on the Denver Fire Department, a DFD Engine Company is equipped with four, 50-foot sections (total of 200-feet) of 2 ½-inch hose, all four assembled into “Denver Hosepack” configurations. In addition, there is a canvas tool bag, with all of the necessary and associated tools and appliances to safely and effectively carry out engine company standpipe operations. Keep in mind, not all four sections (hosepacks) will be taken into the building every time. Usually only three hosepacks (150-feet) are taken into the building, which can easily be carried by three firefighters, along with the standpipe equipment kit (tool bag). In addition, I recommend pairing your engine companies together, so two engine companies will work to carry the necessary equipment into the building and up to the point of operation, and then stretch, charge, and advance the attack line.

To properly assemble the “Denver Hosepack”, you start out 32-inches from the outside of the female coupling. At this point you bend the hose, and start assembling the hosepack into a horseshoe type configuration. It is important to stop your hose folds short of the coupling, and don’t go past the coupling. In addition, the folds should be staggered, one long, one short, similar to the old style accordion hose bed load. This helps keep the hosepack tight and compact (See photos).

When you have made all of the folds and come to the end of the hose, you should ensure that the male coupling ends up on the opposite side of the hosepack from the female coupling. At this point, you should have enough excess hose to attach the male to the female coupling, and tighten, but only a couple of turns is necessary. This serves primarily, to protect the male threads from damage during our day to day operations, such as carrying hosepacks, numerous times in and out of buildings on fire alarms, burnt food, etc.

Lastly, most of the time, you may have some extra hose left over after making all of the folds and attaching the couplings. This extra hose, or slack in the hose, is pulled back to the opposite side of the hosepack, and tucked back into the hosepack between folds. This keeps the extra hose captured tightly into the hosepack, and prevents it from coming loose during transport.

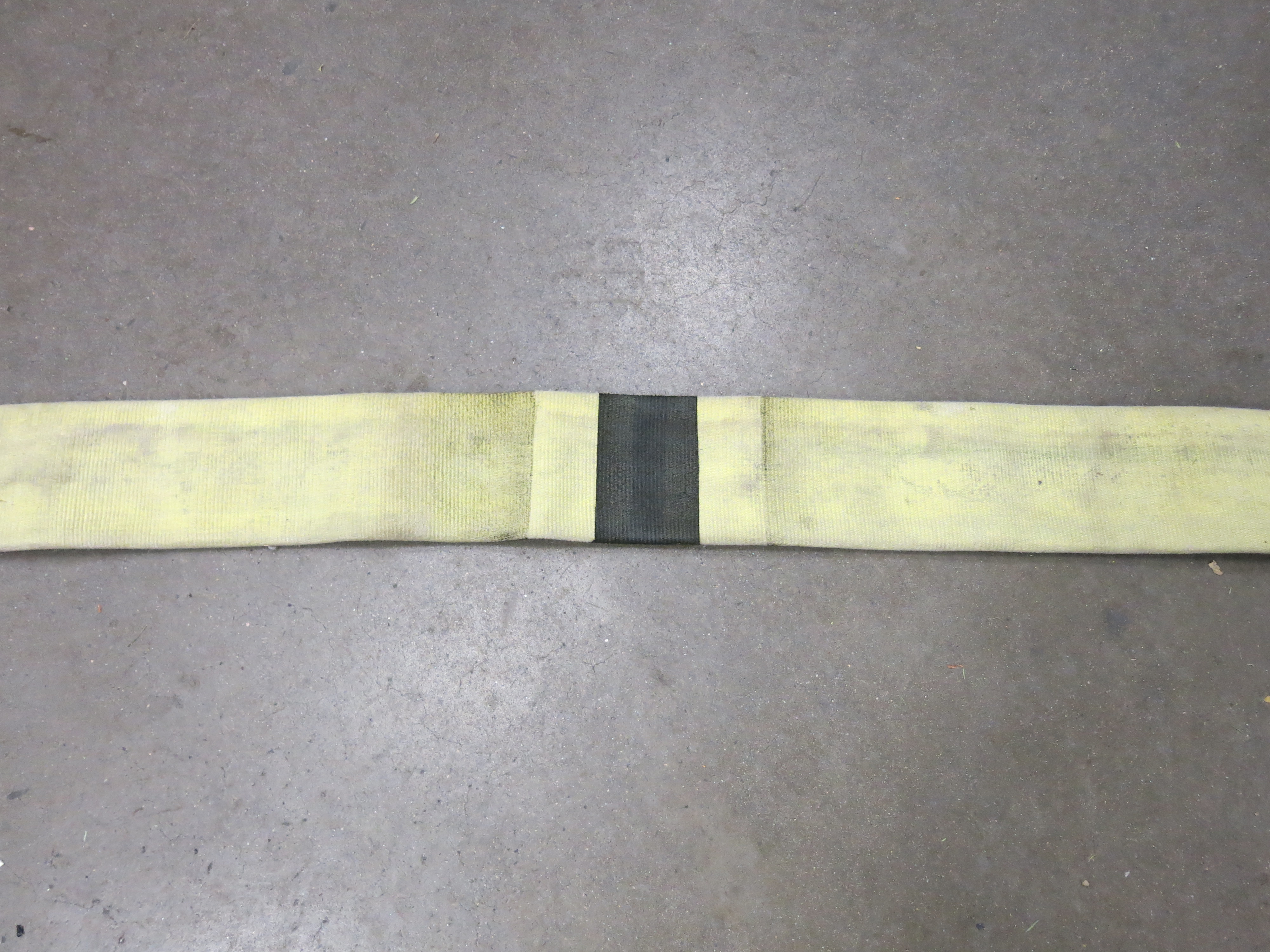

The Denver Hosepack is held together and finished using three, lightweight Velcro straps. Keep it simple here, and once again, avoid crazy gimmicks and expensive gadgets that are all the craze out there. The very best lightweight Velcro strap in the industry was designed and is built by a Brother firefighter from the DFD. Firefighter Brian Jenkinson builds a excellent hosepack strap. It is reasonably priced (lower cost than any other straps I have seen out there), and it is very durable. Brian can be contacted at:

I’m not Brian’s marketing director, but just someone passing out resource information. The strap in question is the 24-inch long, red tab strap, designed for use with 2 ½-inch high-rise / standpipe hose packs (the “Denver Hosepack”).

Always rotate the finished hosepack up onto the flat side before attaching the hosepack straps. Doing this makes it easier to attach the straps properly. Specifically, it allows you to use your body weight to push down on the hosepack, compressing the folds, and makes the hosepack as tight and compact as possible, before attaching the hosepack straps. Ultimately, the hosepack straps will be very tight.

The three straps are placed on the “Denver Hosepack”, with two at the bottom of the hosepack, one on each side, and one near the top, on the same side as the male coupling end of the hose. This is very important, remember; place two straps on the male coupling side, one near the top of the hosepack and one at the bottom. The reason behind this procedure will be comprehensively addressed in a future post, when we complete an “Apartment Stretch” for fire attack.

When placing the straps, remember to always place the bottom straps as close to the end of the hose as possible. This procedure will keep the hosepack tight and compact, and ensure that hose folds at the bottom don’t come loose and cause the hosepack to start coming apart before deployment. Also, train your firefighters to orient the straps in the same position when placing them on the hosepack. This makes it easier to quickly remove the straps during deployment, thus cutting additional seconds from our overall reflex time. A few seconds might not seem like much, but several seconds, here and there, add up to perhaps shaving minutes from our reflex time, thus, we get water on the fire faster.

Of the four recommended hosepacks for an engine company’s high-rise standpipe equipment, three of the hosepacks can and should be assembled as previously described. In addition, I recommend that one of the four hosepacks is assembled into a nozzle section “hosepack. That is, one of the hosepacks should be assembled with the nozzle pre-attached, thus shaving reflex time. When assembling this hosepack, it is built in the exact same manner, except the nozzle ends up in a static position, on the opposite side of the hose pack from the female coupling. And, just like the regular hosepacks, any extra hose should be pulled back around to the female coupling side of the hose pack, and then tucked back into the hosepack between folds

So there you have it. That’s how to properly assemble a “Denver Hosepack”. Once again, just to summarize, I recommend a total of four, 50-foot sections, assembled into four separate “Denver Hosepacks”, with one of the four hosepacks equipped with a nozzle, pre-attached. Use the recipe of 32-inches from the outside of the female coupling to start the pack, don’t go past the couplings with the folds, stagger the folds, and attach the couplings to protect male threads. Rotate the hosepack up onto the flat side to attach the hosepack straps tightly. Two straps on the male coupling side, one on the female side. Straps close to the bottom of the folds.

Give this a try, and let me know if you have any questions. Next time, we will deploy the hosepacks for an “Apartment Stretch”. Stay low!

Below is a short video to tie the whole thing together. Special thanks to the Top Shelf Professional Firefighters of Denver Fire Department Engine Co. 3 who helped me make this short training video. Lt. Phil Miller, Eng. Tommy Martinez, FF. Jim Remley, and FF. Mike Aragon, the Best of the Best.

Here’s the video on how to properly build the “Denver Hosepack”. Please take a look.